The BERtix program can make calculations on meat cooling. It does take account of moisture transport and water evaporation from the product surface. It is not necessary to specify heat transfer coefficients (“alfa values”). Because the BERtix program will calculate these for you. You can use the BERtix program to calculate:

- Cooling time (based on the highest or on the average product temperature)

- Product weight loss

Just define the cooling process and the product

You can specify the cooling process in a number of phases. So each phase will have it’s own conditions in terms of temperature, humidity and air speed. The phases can also include immersion cooling or spray-cooling.

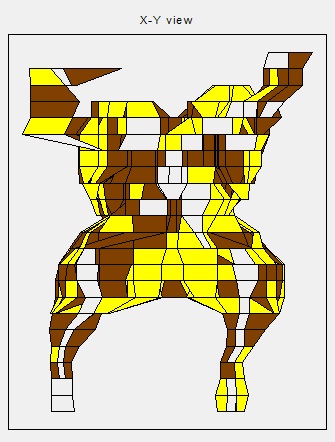

Models for (industrial) meat cooling simulations are provided: Broiler, Turkey (picture left), Pork and Veal. The models give geometry as well as meat, fat and bone distribution. We compared measurements in Dutch slaughterhouses and simulations to validate each of these models.